PUB completes digging works for Phase 2 of Deep Tunnel Sewerage System

Sign up now: Get ST's newsletters delivered to your inbox

The tunnel will be operational by 2026, a year later than previously announced.

ST PHOTO: KUA CHEE SIONG

SINGAPORE - Despite some delays from the Covid-19 pandemic, Singapore is now a step closer to completing a 98km network of tunnels that brings the treatment of used water underground,

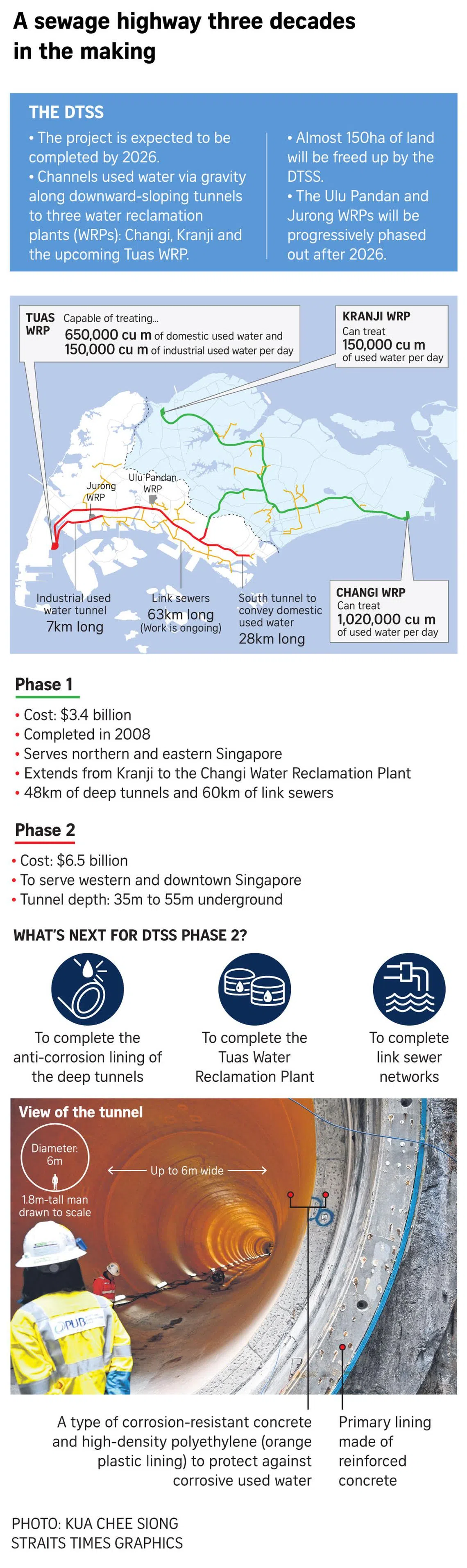

National water agency PUB on Monday concluded tunnelling works for the second phase of the Deep Tunnel Sewerage System (DTSS) – where link sewers convey used water from homes and industries to the deep tunnels, and then to the upcoming Tuas Water Reclamation Plant by gravity, without the need for pumping stations.

The treated used water is then purified to become Newater, which is used mainly for industrial cooling and air-conditioning purposes at wafer fabrication plants, industrial estates and commercial estates.

The tunnels will be operational by 2026, a year later than previously announced.

It will serve the western half of Singapore, including the downtown area and upcoming developments such as Tengah town and Jurong Lake District.

Speaking at a ceremony to mark this milestone, Minister for Sustainability and the Environment Grace Fu, said that the second phase of the DTSS began in 2019, involving more than 5,000 workers at its peak.

“Four years and over 40 million man-hours later, we now celebrate the completion of this remarkable engineering feat,” said Ms Fu, thanking those who had persisted through the Covid-19 years to work on the DTSS.

The ceremony in Jurong East was attended by more than 300 guests, including the pioneer engineers who started the project more than two decades ago.

The first phase of the DTSS, which was completed in 2008, channels used water to the Changi Water Reclamation Plant and the Kranji Water Reclamation Plant for treatment.

Reflecting on the challenges amid the pandemic, Ms Woo Lai Lynn, chief engineer for conveyance of PUB’s DTSS2, recalled how some contractors had to deploy “whatever staff they had on site” – most of whom were supervisors – to complete their tunnelling works as many dormitories were locked down.

Another contractor used new technologies to launch the tunnel boring machine “much faster”, with the whole process monitored and directed remotely from Germany, she added.

“We had minimal people actually on site during that launch, which was amazing,” said Ms Woo.

The tunnelling works were carried out by five different contractors who used pioneering construction methods and smart technologies for smooth and safe operations, said PUB. This greatly reduced the disruption to the infrastructure above ground and to the public, the agency added.

Minister for Sustainability and Environment Grace Fu delivers her speech during the completion of DTSS tunnelling works event on Aug 21, 2023.

ST PHOTO: GIN TAY

Following the completion of tunnelling works, the DTSS will then be fitted with corrosion protection linings, and air jumpers will also be installed to control airflow within the tunnels, so that it is directed to odour control facilities to get rid of the smell.

These are among some of the new features that were implemented in DTSS2 to ensure the integrity of the tunnels and that they are easy to maintain.

Construction workers at the completed Deep Tunnel Sewerage System Phase 2 (DTSS2) Tunnelling Works at the tunnelling site in Penjuru Road on Aug 17, 2023.

ST PHOTO: KUA CHEE SIONG

Both phases of the DTSS cost around $10 billion to build, and the three-node system comprises a 206km-long network of tunnels and link sewers. They are also designed to last for 100 years, benefiting multiple generations, said PUB.

Ms Fu noted that its implementation will allow PUB to reduce the overall land footprint of the used water system across Singapore by half, freeing up to 150ha of land – nearly twice the size of the Botanic Gardens.

For instance, Seletar Water Reclamation Plant was converted into Seletar Aerospace Park after it was demolished, enabling the Government to attract more than $1.5 billion worth of investments, providing over 6,000 job opportunities.

The Bedok Water Reclamation Plant was converted into a four-in-one rail and bus depot.

A key component of the DTSS Phase 2 is the future Tuas Water Reclamation Plant,

For a start, the plant will be able to treat 650,000 cubic metres of domestic used water per day, and 150,000 cubic metres of non-domestic used water.

This would allow the Ulu Pandan Water Reclamation Plant and the Jurong Water Reclamation Plant, which are currently serving the area’s needs, to be demolished post-2026.

The tunnelling works were carried out by five different contractors who used pioneering construction methods and smart technologies for smooth and safe operations, said PUB.

ST PHOTO: KUA CHEE SIONG

During the construction of the DTSS, The Straits Times understands, one of the challenges included developers accidentally drilling into the DTSS tunnel when doing site investigation works for other projects in the vicinity.

While the damage was relatively minor, it was later mandated that developers must have their drilling rigs geotagged, so that an alarm will be sounded if they come too close to PUB’s DTSS project.

Ms Fu said utilities around the world, including PUB, have grappled with rising cost pressures in the production and distribution of water due to higher inflation, energy prices and construction costs.

For instance, DTSS Phase 2 costs almost double of Phase 1 when it was built two decades ago.

“This is why we must right-price water to ensure our water security by promoting conservation and continue investing in essential long-term water infrastructure, such as the DTSS, to support our national development,” Ms Fu said.