Chrome-finished spherical SkyOrb cable cars, customised for Singapore Cable Car (SCC), start taking passengers between Mount Faber and Sentosa Island on March 20.

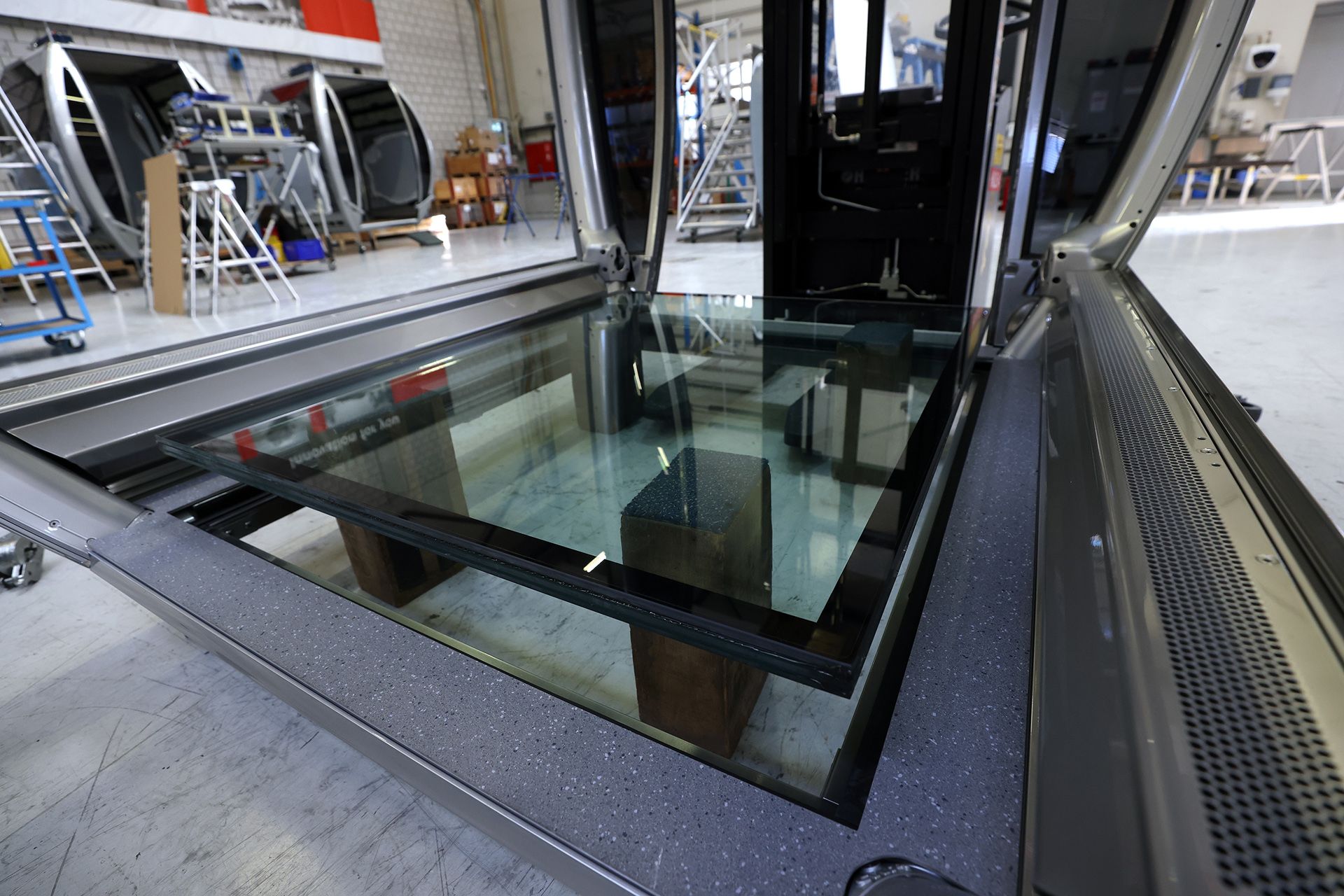

With large porthole windows and glass-bottomed floors, these futuristic pods take to the sky as the company marks its 50th anniversary in 2024.

The SkyOrb is SCC’s fifth generation of cable cars since the attraction was launched in 1974.

On the eve of Chinese New Year on Feb 9, Mr Woo Cheong Yuen arrived at 9am at a warehouse in Tuas, eager to see his festive “gift”.

There, right before his eyes, were seven silvery cable car cabins that had arrived at the port of Singapore after a 33-day journey from Olten, Switzerland, and he immediately fished out his phone to snap pictures to show his family.

“They were like my CNY ang pows,” said the senior manager of technical operations with Mount Faber Leisure Group, which operates Singapore Cable Car (SCC). “After inspecting them, I felt like I could celebrate my CNY in peace.”

The round SkyOrb cabins were set to add a new dimension to Singapore’s skyline, with their reflective exterior that captures and reflects sunlight to stunning visual effect.

Rings of light on two sides of the cabin add another futuristic touch, and can be customised for different celebrations, festivals or events.

Mr Woo, 62, has witnessed all the past four generations of cable cars in Singapore since he joined the company in 1983 as an electrician. “This time it’s different, as the chrome colour and spherical shape have completely changed the traditional image of cable cars.”

On Feb 15, which coincided with the 50th anniversary of SCC, he helped to oversee the unloading of the new cable cars from the warehouse to the Sentosa cable car station.

“All my men were excited, and the whole team volunteered to help out that day,” said Mr Woo, who supervises a team of 42 technicians and 20 contract workers that ensures cable cars run smoothly.

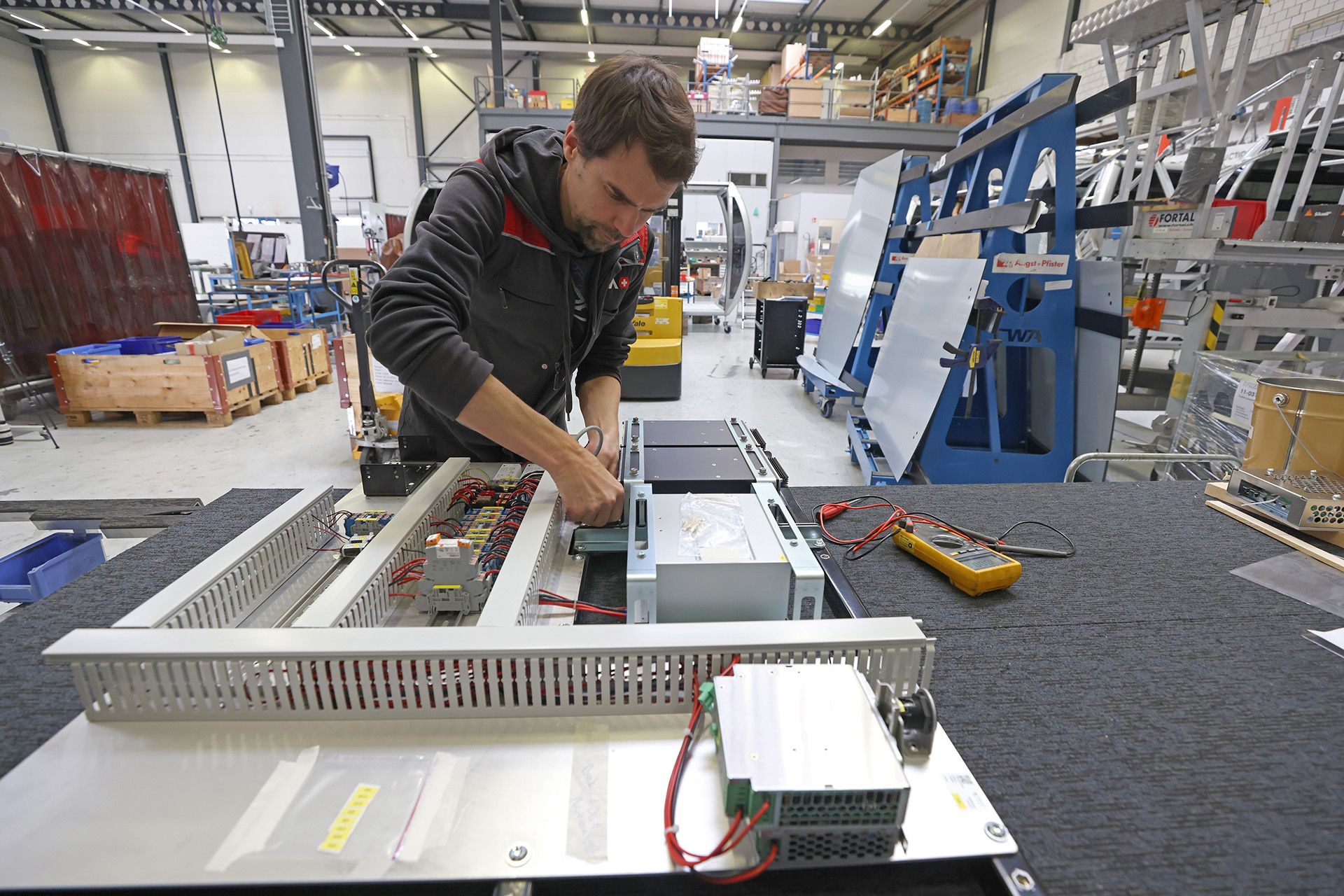

The cabins were inspected before they were carefully hoisted to Sentosa Station in a three-night endeavour, to be prepared for set-up, said Mr Buhdy Bok, managing director of Mount Faber Leisure Group which operates SCC.

“Although these tasks may seem straightforward, their execution demands meticulous planning and coordination, especially given the challenge of handling the cabins’ unique spherical shape,” he added.

Test runs were conducted after system checks, to obtain permit approvals from authorities such as the Building and Construction Authority and the Singapore Civil Defence Force.

“Thorough inspections, maintenance checks and simulations help identify potential issues, ensuring a smooth and secure cable car experience for guests when fully operational,” said Mr Bok.

Finally, on March 15, the spherical SkyOrb cabins were launched.

The new cabins will join the existing fleet of 67 cable cars on the Mount Faber Line connecting Mount Faber and Sentosa Island from March 20.

A round-trip Cable Car Sky Pass, which includes the Mount Faber Line and Sentosa Line, currently costs $35 for adults and $25 for children. SkyOrb tickets will be $15 more for a one-way upgrade to a round trip (between Mount Faber and Sentosa Cable Car Stations).

The Singapore Cable Car has seen more than 60 million riders since 1974, with 2023 combined ridership for Mount Faber and Sentosa Line crossing two million.

Mr Bok said the SkyOrb cabins will elevate the overall guest experience.

Besides being the world’s first chrome-finished spherical cable cars, the SkyOrb cabins have glass-bottomed floors and front-facing porthole windows with more window openings that provide passengers with breathtaking scenery surrounding Mount Faber Peak and a breezier ride.

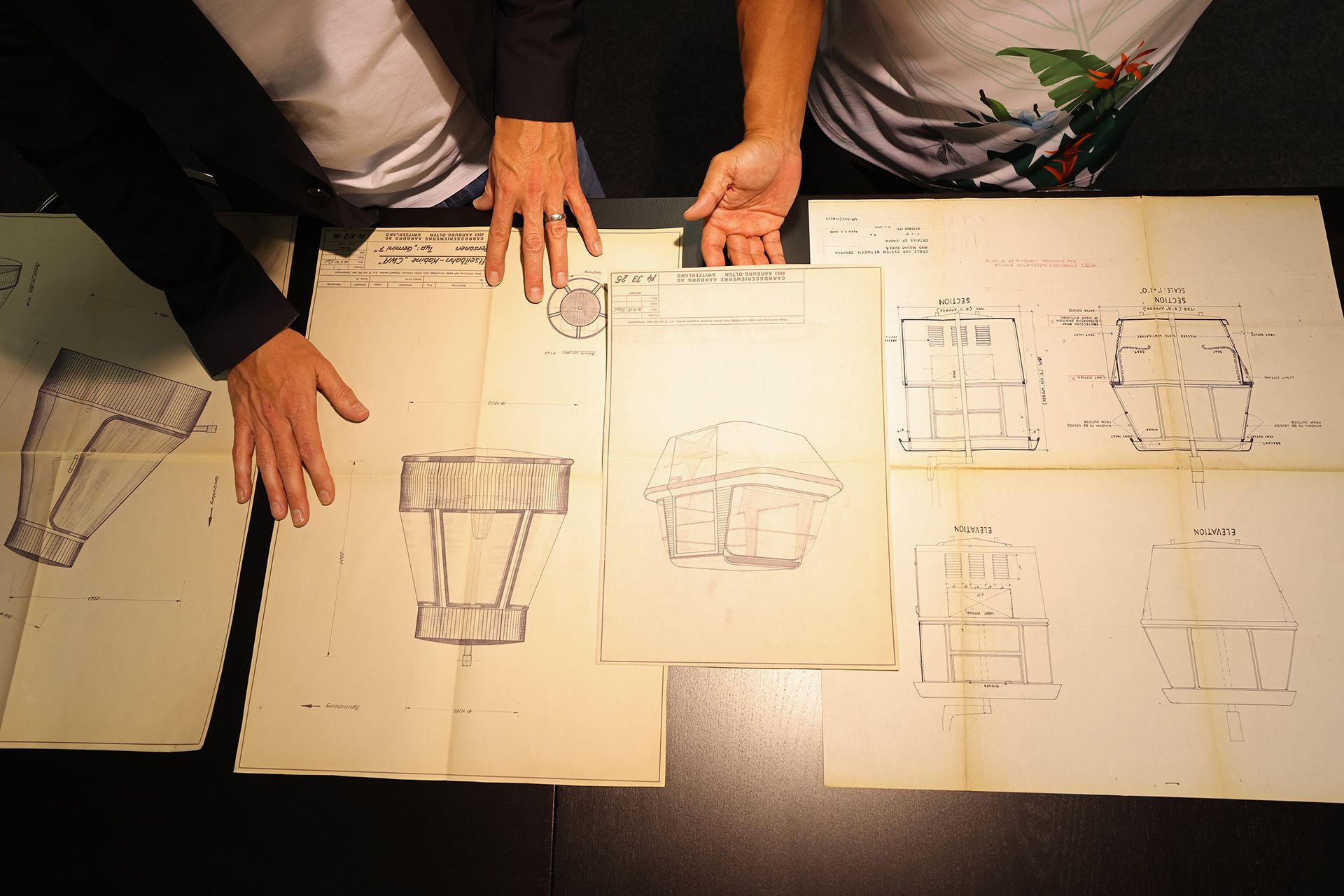

Discussions on the new cabins started five years ago with Swiss manufacturer CWA Constructions SA, the world’s leading manufacturer of cable car cabins and SCC’s go-to supplier for about 50 years.

Mr Christoph Grob, CWA’s vice-president of sales and marketing, said: “The team and I are filled with a sense of pride and accomplishment now that the SkyOrb project is complete. We had been planning and discussing the SkyOrb cabins for five years and are delighted to share this with the world.”

He added: “It is the world’s first chrome spherical cable car cabin, and we are eager to see how the public reacts to this amazing milestone creation to mark Singapore Cable Car’s 50th anniversary.”